SOLUTIONS FOR FERROUS FOUNDRY

ECO-PROJECT

PRODUCTION SINCE 1958

JODOVIT produces some products that allows the achievement of qualitative levels and productive efficiency.

- Reduction of the refining's costs, reduction of feeders and sanity of casts can be obtained by using exothermic feeders or insulating vacuum shapes, produced with ecologic fibres. A vast range of geometric forms is available for every need.

- Feeders with a fast lighting, highly exothermic, with a limited volume of feeding and impervious to the high pressures.

- JODOVIT produces cover insulating and exothermic powders that prevent an excessive retreat of the metal in the feeders with an excellent espandibility and absence of fume.

- The use of refractory coatings based of alcool or water and suitable for every type of application, assures the elimination of surface's lacks of casts, reducing times and costs of refyining.

- Cored pastes, release agents for models and other auxiliar articles complete the range of the products destinated to the foundrie.

VOLUMIX

The very high refractoriness and exothermicity allows it to be used with alloys with a short range of strongly hypoeutectic solidification, spheroidal cast iron with high percentages of chromium, carbon steel, manganese, and all types of bronze.

The exothermic power allows a remarkable reduction of the sand and guarantees a high extension of the geometric cooling module in cm, which varies with the variation of the diameters.

VOLUMIX NETCORE

JODOVIT has developed a new generation of high performance exo-iso fiber feeders, along with breaker core with flexible penetration material and sintering, which guarantee excellent breaking capacity and excellent cleaning of the breaking surface.

The VOLUMIX NETCORE technology has been developed specifically to meet the demand for removal of large riser residues. This eliminates the need for a cutting step in the cleaning process, reducing waste and costs.

Benefits:

- No penetration or sintering of the segmentation animal

- Reduction of processing times and of the materials used. Lower finishing costs and ease of use.

- More flexible placement of feeders in the contours of the casting

- Mechanical machining tolerance reduction. Reduction in component breakage. Waste reduction

- Improved casting surface.

WCOTEX

Water based coatings for shapes and cores for immersion, spray, brush and washing applications.

Availability of a wide range of refractory plasters meeting the needs of the founder for all types of castings produced.

WCOTEX are water-dilutable and are designed for all types of applications.

Supplied in metal buckets and drums, plastic cans and steel silos.

Benefits:

- Wide range available for all foundry applications

- Possibility of studies for specific needs, development of customized products

- Selection of high quality refractory agents to satisfy the most sophisticated technical and environmental requirements

- All packaging options include steel returnable silos with a capacity of 1000 kg

VERNIX

Alcohol based coatings for forms and cores for immersion, spray, brush and washing applications.

Availability of a wide range of refractory plasters meeting the needs of the founder for all types of castings produced.

Vernix can be diluted in alcohol and are designed for all types of applications.

Supplied in metal buckets and drums, plastic cans and steel silos.

Benefits:

- Wide range available for all foundry applications

- Possibility of studies for specific needs, development of customized products

- Selection of high quality refractory and alcohol agents to satisfy the most sophisticated technical and environmental requirements

- All packaging options include steel returnable silos with a capacity of 1000 kg

VEINIX S

The powdered sand additives of the VEINIX S family have been designed to reduce and eliminate crest and / or penetration defects.

They are added directly to the sand destined for the production of cores or shapes. They help eliminate gases produced during the melting process.

The ingredients do not affect the mechanical strength of the cores even at relatively low binder levels.

Benefits:

- A low dosage (1 - 3%) is usually adequate for eliminating problems of ridges with a good cost / benefit ratio.

- The material forms a shock absorbing barrier and reduces the expansion of silica sand.

- Higher dosages make it possible to significantly improve the surface finish.

- The use of VEINIX S reduces the amount of refractory paint used, or even eliminates its use.

SEPAREX

A complete range of release agents to cover all the cast iron and steel foundry needs. The excellent properties of the active release substances contained in the formulations guarantee the possibility of treating areas that are difficult to reach even in the most complex models.

Benefits:

- A specific selection of different products for cold box, hot box, model and mold needs in all materials, application in green sand.

- The use, in the formulations of quality additives, prolongs the life of the equipment.

- Uniform consumption of the release agent avoiding the accumulation of materials.

- Good storage and easy cleaning of the equipment.

- Excellent compromise between environmental compatibility and demanding request of the foundry.

TERMIX

Cover powder anti-retreat, insulating and exothermic, expanded for the mast's covering.

All the range of Termix stresses a reaction in contact with the fused metal, which changes from exothermic to insulating.

All the range is characterized by a lower presence of fume.

Termix are used for cast iron and steel as insulating covering anti-retreat on the feeders where the metal is in contact with the atmosphere.

The quantity and the type of powder depend on the metal and also the diameter of the feeders.

Termix isolate and prevent a high retreat of the metal of the feeders that stoke the cast.

REFRAX

Cast refractories silicon-alluminium for foundries and steel plants

Vast range of forms and dimensions as funnels, tubes, elbows, T and L pieces, reductions, expansion, duck foots e leg tubes, from diam. 30 to 150 mm.

They unit themselves to form the system of cast's casting in cast iron and steel and plates for ingots in steel.

They prevent the pulling of the sand of moulding in the metal.

They allow an high feeding of the cast, reduction of the temperature.

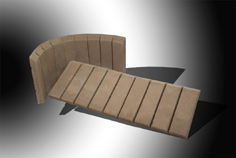

FEEDFLEX

Flexible panels are produced with different compositions of ecological material totally free from FCR (Refractory Ceramics fiber). They can be made of exothermic or purely insulating material. The flexibility of the panel allows both the cast iron and bricks to be replaced in the cast iron and steel foundry starting from a diameter of 450 mm.

The panel can be combined / combined to get up to very high diameters, it can be cut and divided according to the application needs, using a simple cutter.

If inserted in the model with the classic cylindrical shape it can be positioned as a monolithic sleeve.

Benefits:

- Mix of ecological materials free of FCR in respect of the working environment.

- Ease and speed of use, cost reduction.

- Versatility in Iso / Eso materials and dimensional measurements.

- Reduction of waste and packaging

INOCULANTS

One of the most important activity in the metallurgy of modern foundry, is the application of the inoculant process that consist in addition of small amounts of elements to liquid metal just before the casting.

This elements called inoculants, alloe to change and check the metal structure with important phisical and mechanical changes and the negligible variation of the beginning alloy chemical analysis.

CONTACTS

jodovit@pec.it